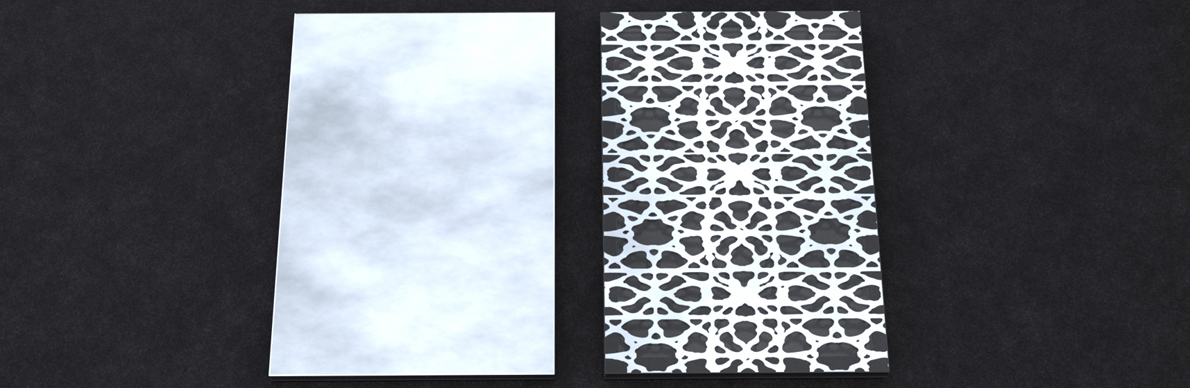

With the new decodesign coatings, arcon has further increased the options available to architects and building planners in the surface design of glass facades. Thanks to its composition, decodesign is weatherproof, making it ideal for use on the outside glass surface. As a result of the manufacturing process, economical project-specific designs, which are suitable for mass markets, can be achieved with this exclusive, aesthetic coating.

In contemporary architecture, the purpose of glass facades is not merely to let light into a building, prevent the penetration of wind and elements, and keep heat in rooms. On the contrary, glass has also established itself as a decorative, style-forming element. Reflective glass facades can also be a means of providing more privacy, particularly in densely built-up urban environments. arcon has incorporated both facets in the newly developed decodesign. The coating now provides architects and building planners with an innovative solution, which not only permits the aesthetic design of individual facades but also of interiors, while remaining an economically viable option.

Screen-free manufacturing process

This is due in part to the highly automated production process, which allows the glass to be manufactured cost-effectively. In addition, arcon uses a screen-free manufacturing process in production. With earlier processes, it was necessary to produce screens which were tailored specifically to the glass. To avoid aesthetic breaks in the facade design, a new screen was required for each individual glass design. This traditional method was used, for example, in the Elbphilharmonie concert hall in Hamburg. The glass patterns used here are highly complex and a distinctive feature of the building. Almost every window in the facade is shaped differently, which required an individual screen to be produced for each shape. With decodesign this is no longer necessary, meaning that exclusive designs of this kind are now also more economically viable. A further advantage of decodesign is that unlike classic screen printing, which is based on burnt-in ceramic colours, this coating does not adversely affect the strength of the glass.

“The technology we have developed significantly reduces the costs per square metre and makes the surface design attractive to a wide target audience“, says Simon Potts, Sales Manager at arcon. Furthermore, the coating can be partially applied to a carrier material (float, tempered safety glass, laminated safety glass) as a tailor-made solution and in accordance with customer requirements.

Particularly weather-resistant

arcon offers decodesign immediately in the color chrome. Gold and copper will follow by the end of 2021. Different levels of light transmission are available for the chrome version. The surface mirror can be used as non-toughened float glass or as thermally toughened ESG/TVG glass (tempered/heat-strengthened safety glass). As a result of the innovative coating design, the change in colour induced by heat treatment is barely noticeable. The composition of the coating makes decodesign particularly resistant to climatic influences. Thanks to its resistance to abrasion, acid and condensation, as well as the high degree of stability demonstrated under exposure to neutral and salt spray mist, decodesign fulfils the requirements of EN 1096-2 class A. As a result, the coating can be used on the outside glass surface (level 1).

The new technology also offers a number of advantages over the previous method in terms of sustainability. In the first instance, less waste is generated as no screens must be produced and, furthermore, the amount of water used during production is significantly reduced. There is also a significant drop in energy consumption, as the panes do not require any additional hardening. In addition, only harmless materials are used in the process.